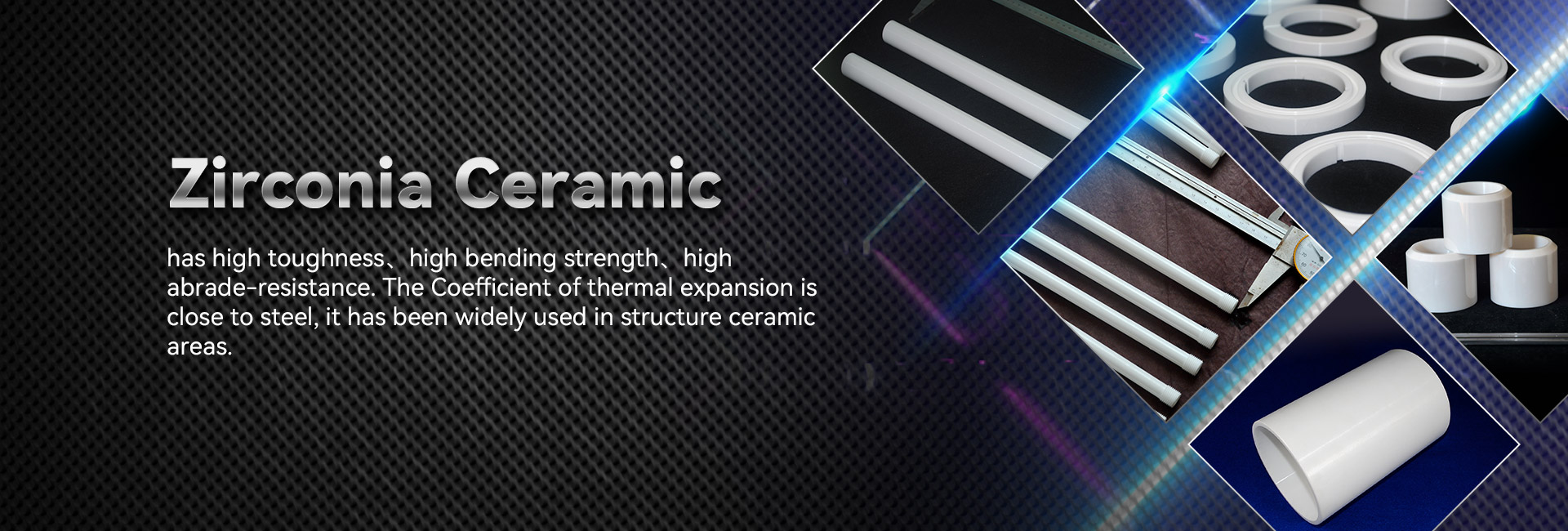

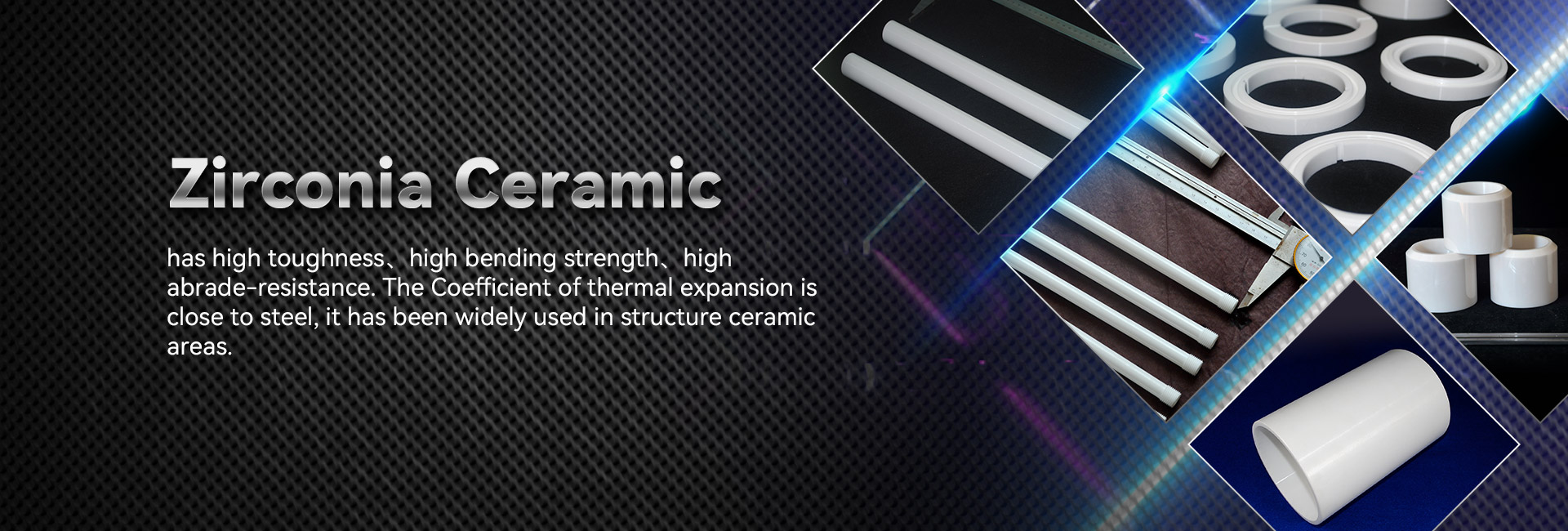

Industrial product possess remarkable compositional traits, positioning them perfect for a varied series of functions. Stemming from aerospace and motoring to technology, these components are constantly developing alumina bar to cope with the expectations of a innovative world.

- Their strength and tolerance to drastic heat levels make them necessary for high-performance systems.

- Furthermore, technical ceramics grant pros in terms of durability, contributing the advancement of revolutionary techniques.

Forming Substances: Built for Exceptional Efficiency

Produced ceramics outperform in rigorous scenarios due to their exceptional characteristics. Constructed from chosen raw compounds and passed through strict processing systems, these high-tech compounds reveal superior sturdiness, corrosion resistance, and endurance to drastic climatic conditions, breakdown, and abrasion. From orbital elements to milling tools, industrial ceramics provide unique quality across multiple areas. Their versatility allows withstanding rugged settings, assuring lastingness and stability. As modernization progresses, the requirement for top-tier tradables grows, cementing the essential role of industrial ceramics in shaping a advanced outlook.

Cutting-Edge Ceramics: Transcending Substrate Margins

Compositions, possessing extraordinary durability and endurance, are experiencing a transformation. Advanced ceramics, engineered with meticulous control over their structure and microstructure, overcoming the confines of the total of conceivable. These compounds offer a expansive assortment of peculiarities, designating them perfect for rigorous realms such as aerospace, health sciences, and resources. From low-weight parts that weather extreme warmth to tissue-friendly implants that integrate seamlessly with the anatomy, advanced ceramics are revolutionizing our sphere.

Exact Ceramic Assembly: Fulfilling Specialized Specifications

Engineered ceramic fabrication has transformed dramatically in recent cycles, enabling the design of complex and highly effective ceramic segments. These segments are vital across a extensive range of branches, including aviation, clinical, and gadget domains. Attaining the exacting standards for these functions calls for careful fabrication tactics that guarantee dimensional precision, surface quality, and material traits. Advanced ceramic fabrication processes implement various methods, including slip casting, injection molding, and additive manufacturing. These processes facilitate the formulation of fine layouts and scrupulous features with exceptional accuracy. Besides, advances in material engineering have resulted in new ceramic recipes endowed with heightened attributes. These materials boast increased longevity, survival, and tolerance to demanding environmental conditions, permitting their use in critical sectors.

The prospects for meticulous ceramic fabrication are vast. As research and improvement proceed, we can await even more cutting-edge methods and composites that will additionally extend the frontiers of what is attainable in this domain.

Elite Ceramic Forms for Harsh Contexts

Engineered ceramic ingredients provide extraordinary hardness and safeguards against severe situations, making them favored for critical ploys in orbital areas. These sophisticated ceramics can bear forceful environmental loads, defy oxidation, and secure their capability under extreme operational pressures. Their singular microstructural elements allow robust output in extreme placements, including hot environments, turbines, and fission plants.

- Ceramic composites

- Heat tolerance

- Enhanced efficiency

Advanced Composites: Consolidating Power and Utility

Blended materials convey a effective mix of mechanical toughness and distinct tailored attributes. Through the combining of ceramic elements within a binder, these mixtures achieve noteworthy qualities. This fusion results in heightened endurance against high temperature stress, wearing, and chemical degradation, rendering them appropriate for rigorous applications in orbital, transportation, and electricity markets. Furthermore, ceramic composites are designed to possess distinct properties like electrical conductivity or biocompatibility, enhancing their employability across diverse areas.

Microscopic Handling in Modern Ceramics

Realizing preferred characteristics in innovative ceramics frequently entails careful regulation over their microstructure. Several handling factors, including sintering firing temperature, interval, and atmosphere, alongside the combination of dopants or secondary phases, notably modify the configuration of particles, permeability, and other microstructural peculiarities. Rigorous adaptation of these parameters allows for the betterment of durability, rupture tolerance, and thermokinetic conductivity. In particular, raising the sintering heat level can stimulate grain growth, thus increasing crowding and improving mechanical rigidity. Conversely, regulating the firing atmosphere may influence the oxidation mode of the ceramic, thereby influencing its electrical conductivity or magnetic aspects. Realizing these relationships between microstructure and properties is paramount for engineering advanced ceramics with fine-tuned features suitable for extensive applications.

Decay-Resistant Ceramics: Improving Longevity

Inside heavy-duty workshop realms, where components are submitted to to constant scoring and wearing, elements with notable erosion resistance are paramountly necessary. Wear-resistant ceramics have manifested as a prime answer, granting unparalleled toughness and operation in broad sectors such as workshop, mining, and aerospace. These modern products possess a distinctive configuration that builds up their capacity to defy scuffing. By utilizing the fundamental toughness and density of ceramic substances, engineers can manufacture long-lasting components capable of enduring the most extreme operating settings.

Biocompatible Compounds: Purposes in Biomedical Field

Medical-grade ceramics have changed the health realm, presenting an array of profitable aspects for various purposes. These materials are non-reactive within the human body, minimizing immunological responses and encouraging regeneration. A prime application for biocompatible ceramics is in surgical implants, where their sturdiness sustains long-lasting backing to damaged organ structures.

Equally important, they are exploited in dental prosthetics, supplying a robust and aesthetically pleasing solution for oral reconstruction. Ceramics also assume a key position in medication delivery, enabling the specific distribution of compounds to specific points within the body.

- Besides, biocompatible ceramics are growingly being analyzed for biomaterials development, serving as a platform for cell growth.

- For that reason, the road ahead of biocompatible ceramics in medicine looks encouraging, with continual studies expanding their functions.

Ceramic Sensors: Driving Exact Evaluations

Ceramic sensors have appeared as fundamental components across a wide array of industries. These detectors leverage the special traits of ceramic elements to deliver highly exact determinations. Their robustness in {demanding|harsh|