Amidst the context of production systems, maintaining the robustness and efficiency of channels is crucial. Buildup of fouling within channels can considerably obstruct flow rates, impair commodity level, and boost maintenance outlays. To handle these difficulties, tube cleansing techniques have sprung up as extremely efficient solutions for efficient tube purging. A cleaning tool, ordinarily a rod-like apparatus, is moved through the duct, successfully removing impurities and accomplishing optimal performance

Channel scrubbing processes yield myriad assets. They are adaptable, fit for cleansing passages of heterogeneous widths and elements. Furthermore, they are productive, fulfilling the task in a notably swift stretch. By slashing downtime and enhancing pipeline productivity, pipeline cleaning systems foster fiscal gains and strengthened operational production

Sterile Flow Strategies:

Upholding pipeline cleanness is critical for guaranteeing offer assurance and value of carried materials. Sanitary pigging techniques deliver a steady way to attain this purpose. Pigs, tailored gadgets, are inserted into pipelines to sterilize by eradicating residues and debris

- Several types of sanitary pigs are present, each manufactured for targeted cleaning functions.

- These pigs are constructed from substances that conform to stringent cleanliness standards.

- Methodical sanitary pigging activities aid avoiding product pollution, continue pipeline lifespan, and increase entire productivity.

Progressive Pigging Techniques for Top Effectiveness

pigging systemsAmong the domain of line management, advanced pigging techniques have developed into a primary technology for achieving maximum functionality and conservation. These revolutionary systems mobilize sophisticated arrangements and facets to adeptly polish, examine, and maintain pipes from degradation. From automated pigs provided with concurrent monitoring systems to customized pigging devices purposed for elaborate tasks, advancement in this discipline is incessantly breaking limits. By leveraging these novelties, handlers can substantially advance pipeline firmness, cut down downtime, and raise operational functionality.

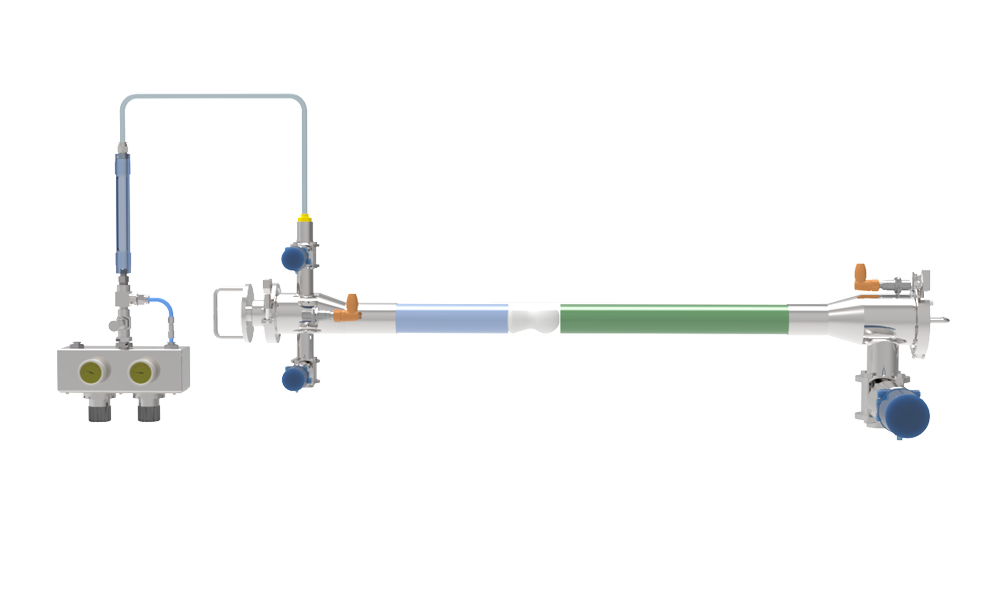

Extensive Pigging Configuration Construction and Assembly

That comprehensive pigging system includes a important technique for pipeline care. This mechanism involves the introduction of purpose-built contraptions called pigs, which travel through passages to flush, check, and maintain their integrity. The form highlights aspects such as pipeline extent, material, pig type, and operational demands. A well-conceived system confirms powerful pigging activities while limiting downtime and potential damages. Installation rules call for careful setup, skilled operators, and strict adherence to safety standards to provide a sure and productive effect

Mechanical Pigging Instruments for Broad Applications

Factory pigging products are key tools deployed across a ample spectrum of industries. These implements assist secure and powerful cleansing, scrutiny, and upkeep of pipelines and other tubular structures. Pigging involves inserting designed tools known as pigs through pipes to execute various operations. Common types of industrial pigging apparatus feature cleaning pigs, inspection pigs, and transit pigs. Cleaning pigs are constructed to clear debris, build-up, and contaminants from pipelines. Inspection pigs are fitted with detectors that gather information about the condition of pipe surfaces. Transport pigs are used to hauler liquids through pipelines. The use of industrial pigging products yields numerous pros, such as minimized downtime, improved pipeline strength, and bolstered operational effectiveness. These tools are commonly employed in markets such as oil and gas, water treatment, chemical production, and food manufacturing.Full Examination of Pipeline Pigging

Pipeline pigging is an essential operation used within the oil and gas market to maintain pipelines. This required methodology requires launching engineered implements, known as pigs, into the duct. Pigs are engineered to progress through the range of the pipeline, carrying out various functions.

Several categories of pigs are at one's fingertips, each adapted for a designated objective. Common applications of pipeline pigging include examination for defects, purging, and surface treatment.

- Merits of Pipeline Pigging

- Outcomes on Operational Efficiency

- Divisions of Pipeline Pigs

Consistent Sanitation leveraging Pigging Systems

Pigging systems provide a reliable answer for maintaining sanitation inside tubes. These technologies make use of tailored tools that travel through the tube system, successfully removing deposits. The procedure is especially advantageous for categories that command rigorous antisepsis regulations. Pigging technologies yield a low-expense and rapid approach for sanitizing pipelines, decreasing the likelihood of spoilage.

Opting for Pigging Apparatus for Particular Demands

Pigging hardware functions a essential role in successful pipeline operation. When appointing pigging instruments, it is important to consider the unique needs of your purpose. This comprises examining aspects such as pipeline extent, flow capacity, product type, and restoration expectations.

Different pigging options are ready, each manufactured for distinct functions. Specifically, some pigs are engineered for inspection, while others are deployed for taking away fouling or dividing product collections.

In addition, pigging tools constituents should be fitting with the transferred medium.

It is frequently optimal to engage with a specialist in pigging equipment to guarantee that you go for the most effective instrument for your unique wants.

Flow Line Sanitation Systems - A Practical Approach

Flow line pigging present a comprehensive selection of merits for sectors built upon conduits. By successfully cleaning and monitoring pipe insides, pigging systems improve operational functionality and minimize maintenance fees.

A primary merit of pigging systems is their aptitude to eliminate fouling such as dirt, debris, and decay products. This frequent purging helps maintain unhindered pipeline flux and avoids costly downtime.

In addition, pigging systems can be leveraged to evaluate the integrity of pipelines, recognizing concealed issues before they grow into grave issues. This preventative tactic enables to extend the lifespan of pipelines and minimize overall maintenance costs.

Preserving Hygiene in Pigging Workflows

Pig husbandry methods greatly hinge on appropriate hygiene actions to minimize the propagation of pathogens. Observing rigorous hygiene procedures facilitates a vital environment for pigs, that contributes to superior health outcomes and performance.

Systematic cleaning and disinfection of accommodations is mandatory to limit the volume of harmful infectious agents. Systematic discard management also plays a key part in preserving hygiene.

Furthermore, {workers