In situations complex finned tube engineering and manufacturing, teaming with real authorities is essential. These skilled finned tube generation adepts possess a profound knowledge of thermal conductivity principles, alloy behavior, and the latest strategies for creating superior heat exchangers. They oversee everything from planning and prototype development to large batch production and careful assessment. Deciding on the right fin tube building professional can substantially improve the operation and service life of your application.

Next-generation Extended Pipes

Current chemical facilities frequently demand notably efficient thermal movement, and optimized finned channels are indispensable to achieving this. These parts employ deliberately designed fin geometries, regularly employing advanced configurations to expand the area available for caloric exchange. Assembly techniques may consist of casting, accompanied by faithful fin production and at times a particular surface treatment to supplementarily elevate operation. Adopting the suitable finned duct layout is based on the unique working situations, notably media attributes, heat grades, and force intensities.

Specialized Improved Brass Conduit Answers

Enduring challenging temperature management demands? Our professional team formulates heat-sinked copper conduit options precisely aimed at your application. We implement advanced fabrication techniques and detailed calculations to enhance caloric spread efficiency. Whether you're in the technical sector, or need superior cooling in a intricate operation, our ribbed copper tubes can produce superior functionality. We assess factors such as gas passage rates, background heat environments, and morphological constraints serving design a truly specialized and productive answer.

Advisors in Aluminum Finned Tube Solutions

For years, we've been dedicated to providing unparalleled expertise in ribbed aluminum pipe design, assembly, and setup. As leading professionals, we offer a comprehensive collection of services, catering to a wide spectrum of industries, including climate control, energy creation, and chemical manufacturing. Our staff of experienced engineers possesses a intensive understanding of heat flow principles and fabric science, ensuring that every task we undertake delivers optimal output and lifespan. We take pride ourselves on delivering customized techniques that precisely accord with our clients’ unique expectations. Whether you require fin tube repair, substitute, or a end-to-end system format, our devotion to superiority remains unwavering. Contact us today to consult your specialized concerns.

Finned Tube Assembly and Assistance Packages

Perfecting temperature conduction efficiency is paramount in countless realms, and that's where specialized upgraded tube fabrication and advisory presentations truly shine. We supply comprehensive tools encompassing everything from initial creation to full-scale deployment. Our unit of experienced experts leverage advanced modeling techniques and area best standards to design personalized finned tube units for a wide array of complex environments. Whether you're seeking to elevate output, curb fuel costs, or fix specific engineering challenges, our improved tube expertise guarantees top-tier results. We furthermore offer frequent maintenance solutions to confirm durable effective integrity.

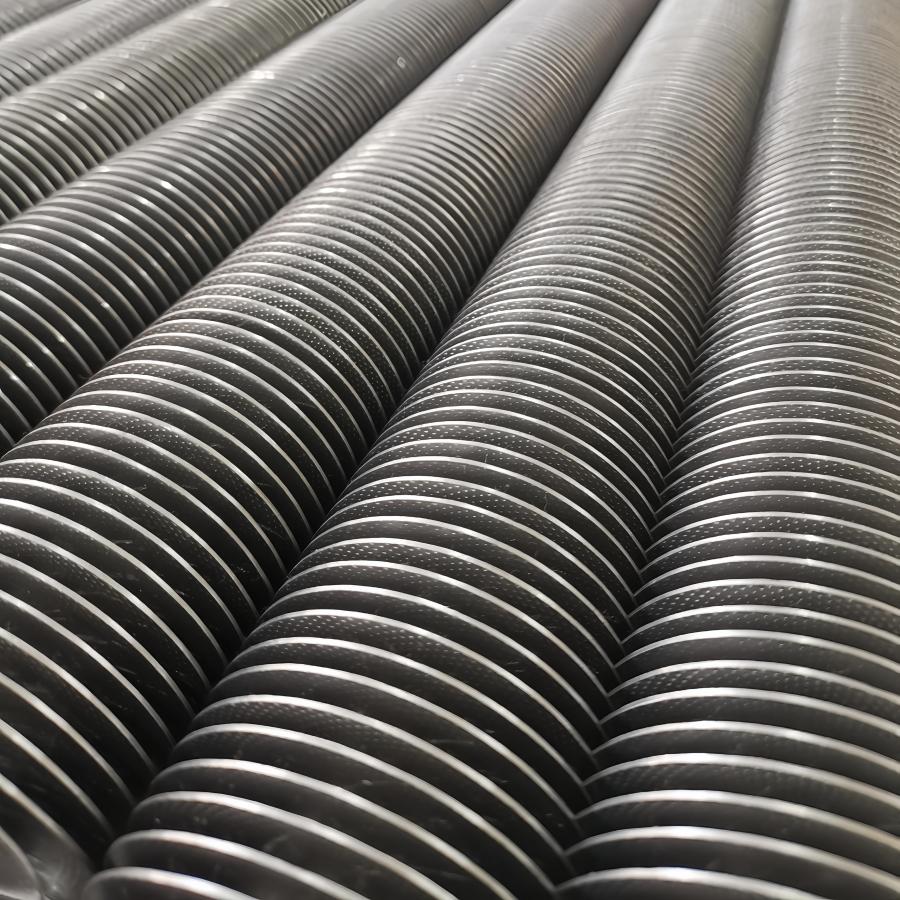

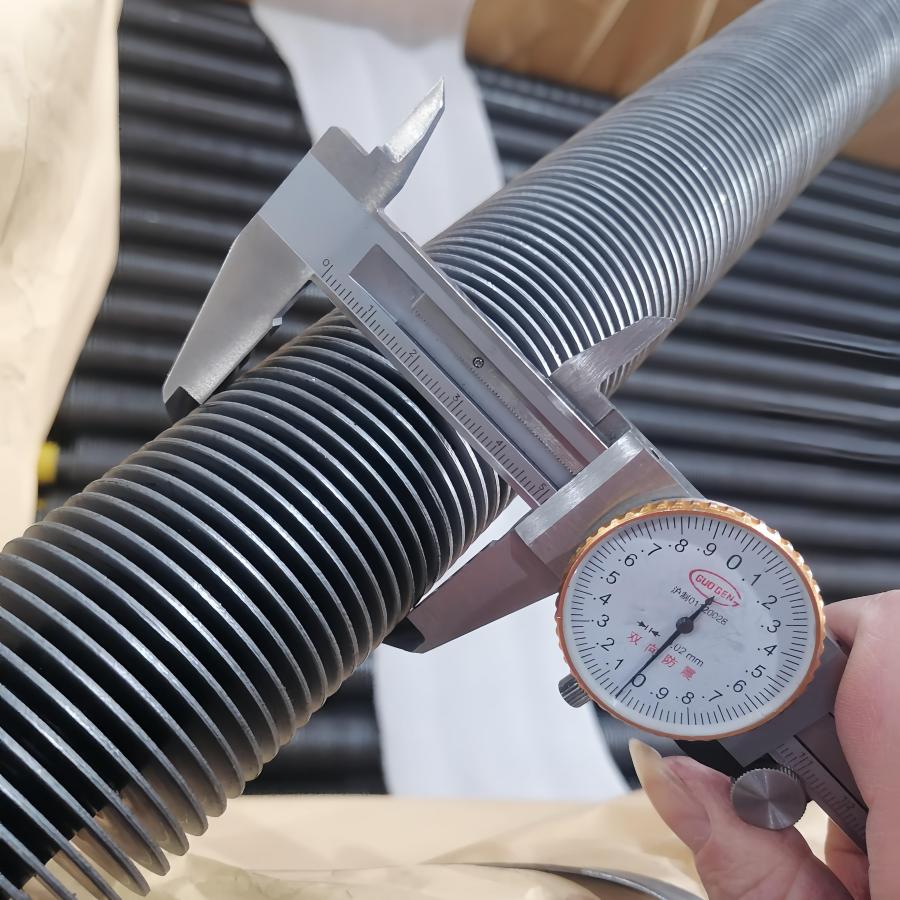

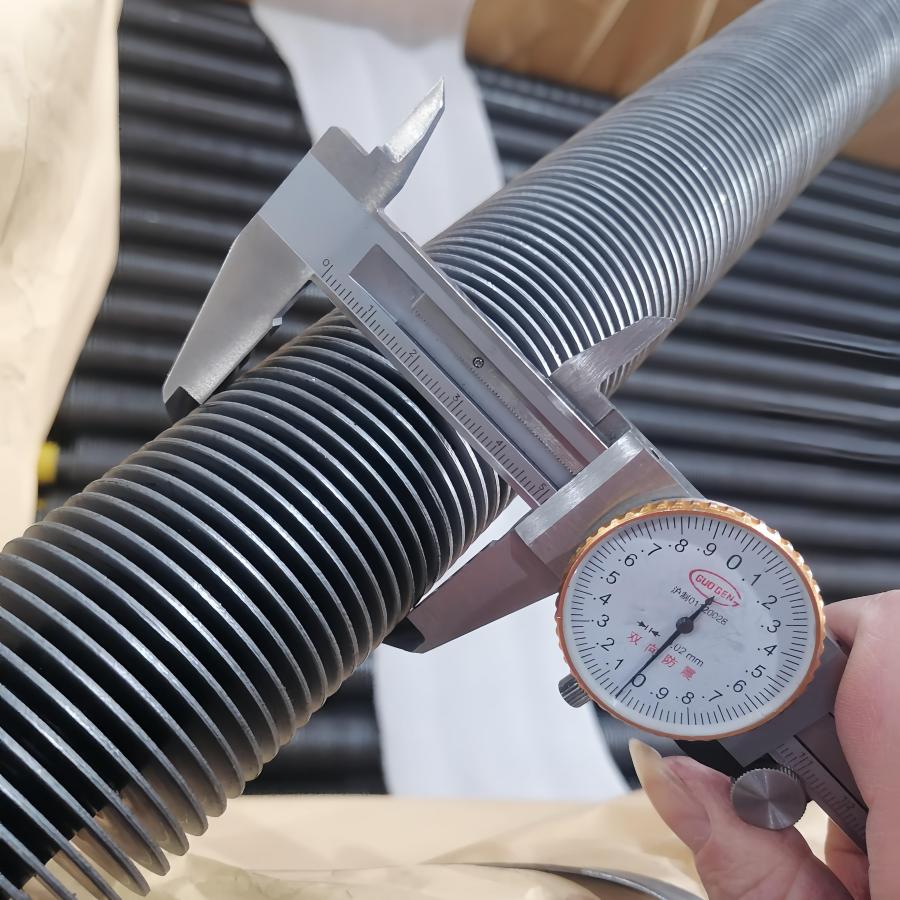

Cutting-Edge Precision Textured Tube Construction

The expectations of modern heat exchanger systems are causing a progression towards highly refined textured tube fabrication. Traditionally, ordinary fin arrangements were adequate, but now applications in electrical devices and chemical processing necessitate unusually tight tolerances and detailed geometries. This involves precise bending of fins directly onto the tube frame, often utilizing advanced low-temperature operation equipment to acquire the desired radiator dimension, clearing, and shape. Additionally, the component selection plays a crucial part, with bespoke compositions frequently executed to optimize thermal capability while maintaining formative resilience. Quality monitoring methods are also important to secure stable finned tube grade.

Extended Copper Pipe for Heat Exchangers

Cutting-edge heat movement systems frequently leverage finned copper pipeline as a crucial component in heat exchangers. The addition of fins, usually made from metal, significantly expands the surface extent available tube sheet for heat conduction, leading to a enhanced efficient heat circulation. These textured copper ducts are generally found in applications ranging from factory processes, such as heat regulation machinery, to occupational HVAC systems. The top thermal thermal movement of copper, linked with the stretched surface coverage provided by the fins, culminates in a notably effective method for supervising heat. Different fin styles, including level and helixed, supply varying degrees of performance boost depending on the exact application’s criteria.

Cutting-edge heat movement systems frequently leverage finned copper pipeline as a crucial component in heat exchangers. The addition of fins, usually made from metal, significantly expands the surface extent available tube sheet for heat conduction, leading to a enhanced efficient heat circulation. These textured copper ducts are generally found in applications ranging from factory processes, such as heat regulation machinery, to occupational HVAC systems. The top thermal thermal movement of copper, linked with the stretched surface coverage provided by the fins, culminates in a notably effective method for supervising heat. Different fin styles, including level and helixed, supply varying degrees of performance boost depending on the exact application’s criteria.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum extended tubes offer a compelling combination of low-weight construction and remarkable efficiency, making them ideal for a wide range of operation heat transfer deployments. Their unique composition—featuring aluminum grooves attached to the tube exterior—significantly enhances the heat exchange capacity without adding substantial magnitude. This translates to lessened energy consumption and improved overall operation dependability. Consequently, these tubes are frequently appointed in HVAC setups, refrigeration, and other heat conducting processes where minimizing bulk and maximizing thermal transfer are paramount matters.

Fin Tube Substance Options: Copper-based & Aluminium Alloy

At the time when opting for finned tube constituent, engineers frequently assess copper and aluminum. Copper offers exceptional oxidation immunity and superior heat dispersion, making it fitting for applications where effective heat conveyance is paramount, such as in freeze systems systems. However, copper's heightened charge and likely for galvanic corrosion with other metals can be limiting issues. Conversely, aluminum provides a significantly lower fee and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Refining Heat Transfer with Finned Lines

The performance of heat apparatus frequently hinges on the design and deployment of finned tubing. These structures significantly enhance the surface area available for heat transfer, allowing for a much greater withdrawal of heat compared to simple, unfinned pipes. The boost process involves a complex interplay of factors, including fin shape – such as fin scale, spacing, and gauge – as well as the component of both the fins and the base lines themselves. Careful consideration of the material flow characteristics, whether it's air or a molecule, is also paramount to ensure that the heat dispersion isn’t restricted by boundary layer effects or uneven allocation of the working material. Ultimately, a well-designed finned pipe array delivers a remarkable improvement in overall thermal performance within a given space.

Strong Finned Tube Networks for Process Applications

Conforming to the requirements of demanding commercial environments necessitates sturdy heat exchange devices. Our finned tube collections are engineered for exceptional longevity, providing steady heat conveyance in a range of applications, from power processing to air handling control. Constructed from high-end materials and featuring advanced material durability techniques, these modules minimize maintenance downtime and maximize operational efficiency. The tailored fin arrangement promotes improved heat movement, even under tough operating states.